Overview

Artificial insemination is used in approximately 84% of commercial and stud stock dairy herds [4] forming part of the routine management. The dairy industry has used AI to maximise the genetic improvement tools that are available.

The use of AI is very common in stud beef herds where breeders are seeking to produce elite bulls for sale or on farm use. In recent times commercial beef breeders are utilising AI to improve the quality of their female herd and also their steer progeny to ensure they are consistently meeting their market specifications. Developments in the field of fixed-time AI (FTAI) also offer managerial benefits in addition to the genetic improvement gained from AI. These advances are seeing AI rapidly adopted in the Australian beef industry.

How do producers use AI?

There are two methods of implementing an AI program into either your dairy or beef herd, through heat detection, or FTAI. The best choice for your herd depends on your circumstances and what your breeding objectives are. It is always a good idea to discuss your options with your veterinarian or an expert.

Heat detection and AI:

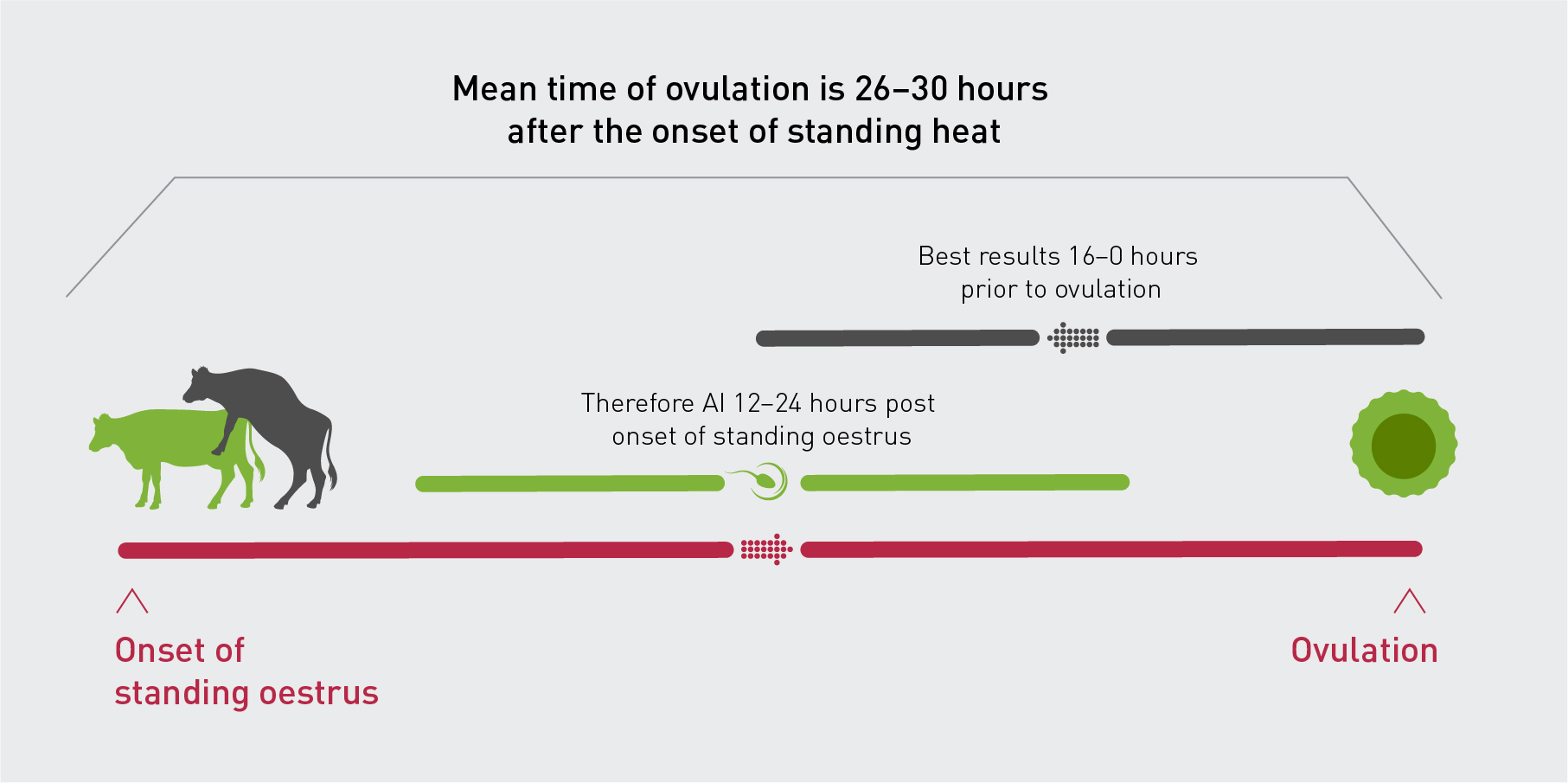

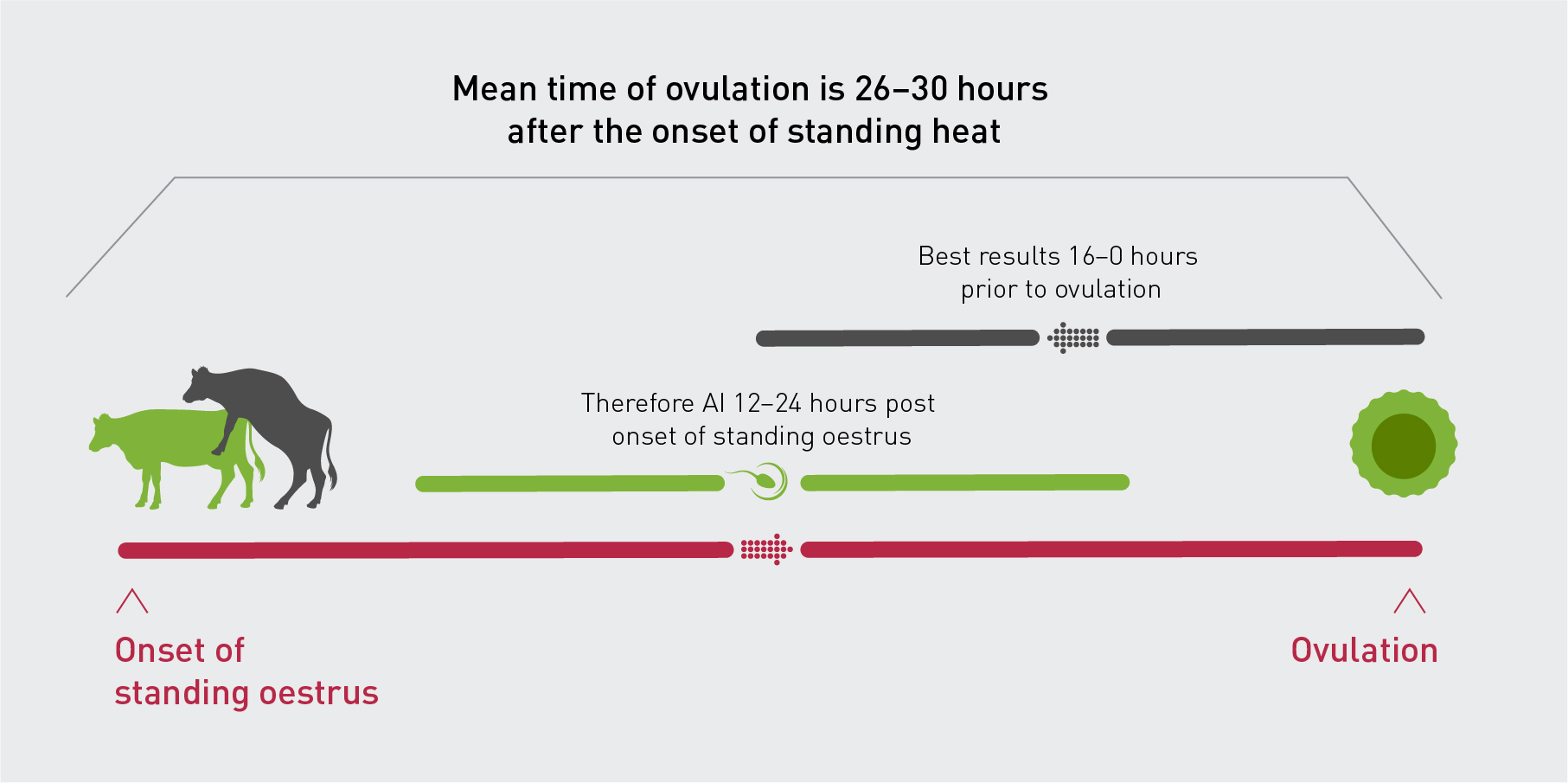

Heat detection and AI requires the accurate detection of when the cow is in ‘standing heat’ or is in oestrus. Ovulation on average occurs 26 to 30 hours after the onset of standing heat. To get the best result, the aim is to have the female inseminated 0 to 16 hours prior to the time of ovulation. As frozen-thawed sperm does not remain viable for as long as a natural ejaculate, it is necessary to AI close as possible to the time of ovulation. It is recommended that the female is inseminated 12 to 24 hours after the onset of standing heat (Figure 1). Usually at this point in time, the female is no longer in standing heat. A common mistake is to inseminate the females too early, failing to acknowledge the long duration from the onset of heat to the time of ovulation.

Figure 1: Timing of ovulation relative to the time of standing heat or oestrus.

For optimal results, it is critical that heat detection is accurate. It is recommended that heat detection is carried out twice daily for at least 45 min intervals by trained personnel. Use of heat detection aids can be used to indicate whether or not a female has been in standing heat, but this should not substitute physical observation of the females. If heat detection is inaccurate then females may not be submitted to AI OR be inseminated at the wrong time, both contributing to low number of calves born to AI and delayed conception in the cow herd.

Producers will use heat detection and AI when…

-

They personally have the skills to AI or have on farm staff that can AI and are readily available to inseminate cows/heifers as they present on heat.

-

There is sufficient and available trained labour on farm to observe for heat.

-

Cows can be individually identified, drafted and separated for AI.

-

Semen is expensive or rare, ensuring that each cow that receives a dose of semen has had a true heat.

-

Small mobs are being submitted to AI – usually < 50 head.

Fixed-time AI (FTAI):

FTAI enables 100% of the mob to be submitted to AI without the need for any heat detection. It is necessary to synchronise the time of ovulation of each female in the herd using a synchronisation protocol so that the AI activity can occur at the one time for the whole herd. The aim is for the majority of the herd to ovulate within a 12 hour window after the time of AI.

Administering synchronisation treatments for FTAI can be performed by farm staff with basic training. The synchronisation products are supplied by your veterinarian and/or your AI provider. It is extremely important that the protocols are followed, taking care to administer the correct dose and adhere to the correct times listed. When good quality assurance is exercised throughout the entire FTAI process, the chance of the best possible result is increased.

There is a variety of common protocols that suit most beef and dairy herds. However, if you have a particular objective for your herd, it would be worth discussing your options with a veterinarian or an expert as there is often flexibility in the protocols to suit your management situation. There are many managerial benefits to using FTAI, see our articles and case studies section to see evidence of how FTAI has improved on farm management of beef and dairy herds.

Producers will use FTAI when…

-

There are no skilled AI technicians on farm, or the on farm technician is inexperienced in larger groups of animals.

-

There is no provision of labour to accurately detect standing heat.

-

Drafting and separating cows in standing heat is difficult or stressful to cattle/personnel, or they would like to spend less time on these activities.

-

Semen is abundant or affordable.

-

Mob sizes are large.

-

There is a desire to reap the benefits of tighter calving and fertility improvements through synchronisation.

-

Collect semen from sires that are on farm, and use chilled in an FTAI program.

Combination of heat detection and FTAI:

Why not make the most of what each technology can offer? In some programs, females are synchronised for FTAI. The operator will then heat detect the females up to 48 to 72 hours after the time the Cue-Mate® is removed. When the heat detection period has ceased, the balance of the females that have not been observed in heat, are FTAI. In these programs, the operator may choose to use more expensive or rare semen in these females that have been observed in heat, and a lower value or surplus semen in the females that are FTAI. This is an example of the many options that are available in protocol design and it is worth discussing your options with your veterinarian or expert.

Heat detection vs. FTAI

Pros

-

100% of the mob is submitted to AI.

-

Activities are pre-planned at a particular time and day.

-

Easier to plan off-farm labour.

-

The whole mob is synchronised to one day.

-

Calving occurs over a shortened period, early in the season.

-

Earlier calves are heavier.

-

Stimulates cows to cycle after calving.

-

Generally results in more calves being born to AI.

-

Don’t miss any cycles due to silent heats.

-

Synchronisation treatments may treat some reproductive disorders.

-

An excellent protocol if you collect and chill semen to be used within a specific timeframe.

Cons

-

A semen straw is required for every female in the program.

-

Synchronisation treatments can be more expensive than heat detection, but is often offset by labour and managerial benefits.

-

Unless intensive re-synchronisation programs are run, physical sires are still required.

Heat Detection AI

Pros

-

Great for when semen is expensive or rare as only females that have been observed in heat are AI.

-

If an AI technician is on farm, and there are small numbers in the mob, this may be a more affordable option.

-

Some producers are more comfortable when they have observed the female on heat.

Cons

-

Accurate heat detection is required – costly in terms of labour.

-

Risk of missing cows in heat, delaying the time to conception e.g. cows that have silent or discrete signs of heat such as lactating dairy cows.

-

Requires drafting facilities to separate animals on heat.

-

Labour tends to be costly.

-

Generally results in fewer calves born by AI sires than when using FTAI.

Expected Results

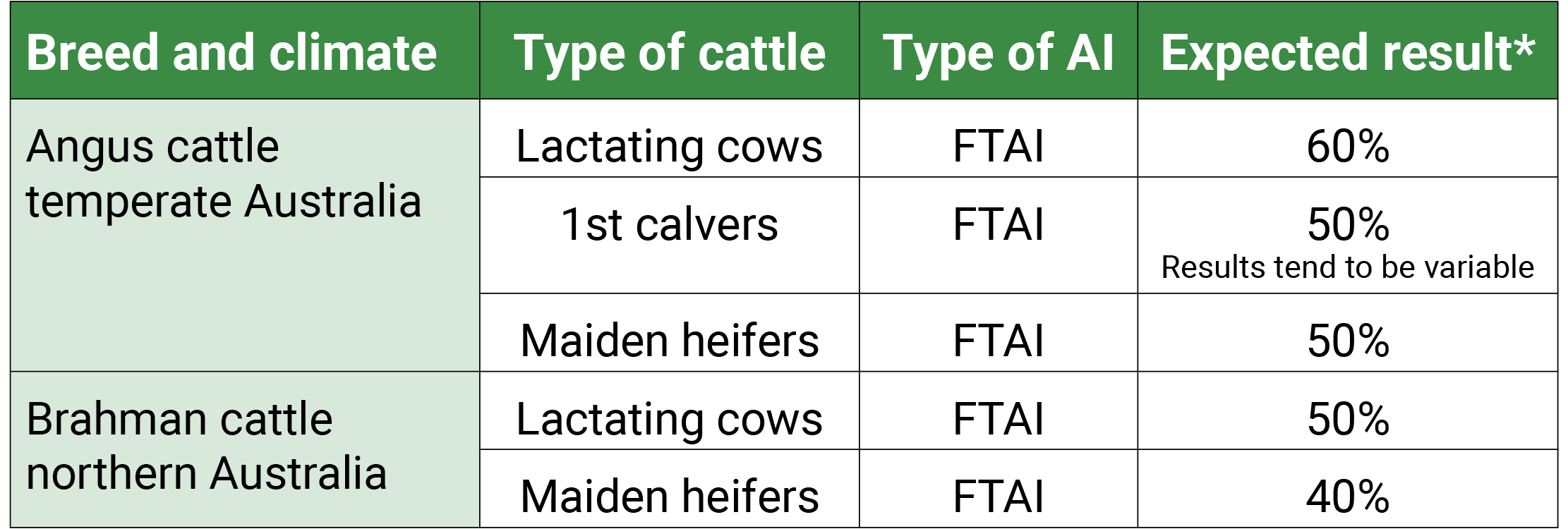

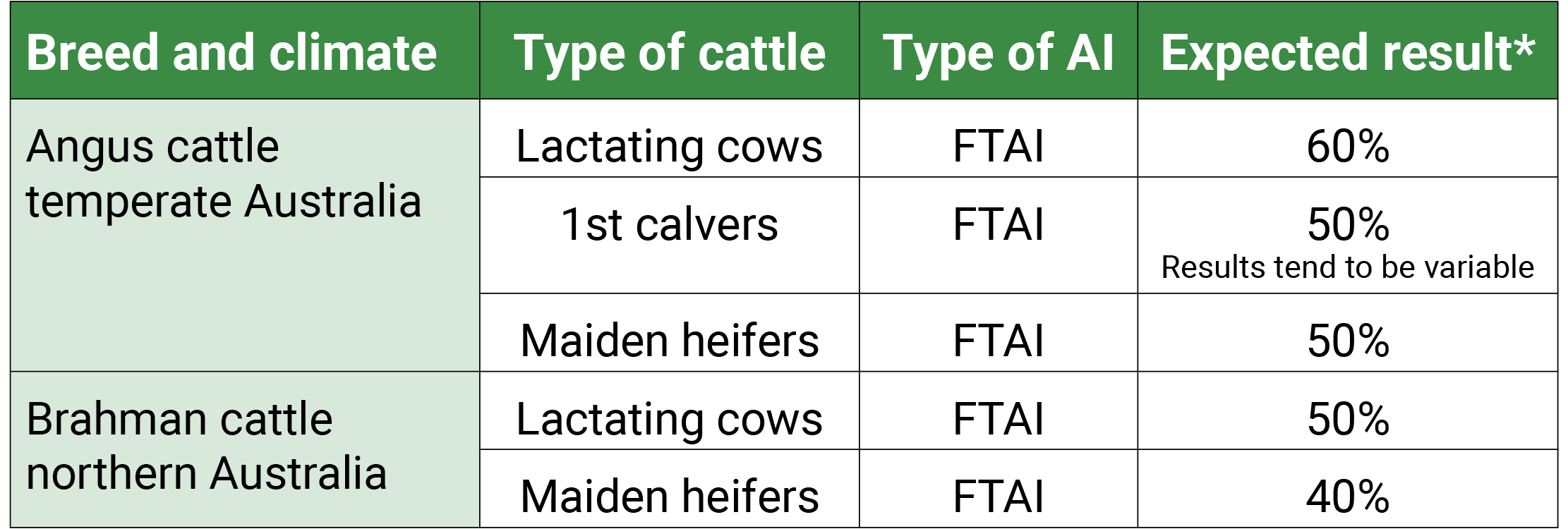

Expected results from AI programs are highly dependent on a variety of factors. Key factors affecting the outcome of AI programs are as follows:

*Expected results are what is on average experienced in these types of cattle, typically results may be lower or higher than what is reported. The actual result can readily vary within ± 5% of the reported average. Failure to comply with best practice management or factors negatively affecting the cattle as reported above may also contribute to a negative result.

Products used